Versatility and Applications

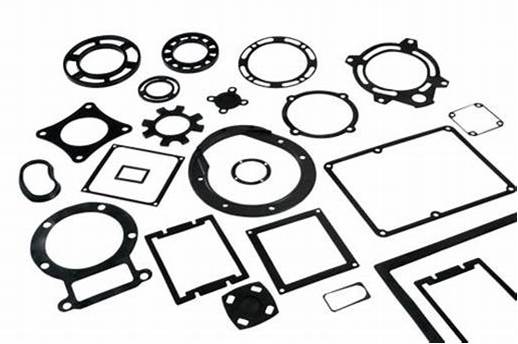

Rubber products are highly versatile and used across numerous industries including automotive (tires, seals, gaskets), healthcare (gloves, tubing), and consumer goods (shoe soles, rubber bands). This versatility is due to rubber’s unique properties such as elasticity, durability, and resistance to water and chemicals.

Types of Rubber

There are two main types of rubber used in the industry. natural rubber, derived from the latex of rubber trees, and synthetic rubber, produced through the polymerization of monomers like styrene and butadiene. Each type has different properties and is chosen based on specific application needs.

Environmental Impact and Sustainability

The rubber industry faces environmental challenges, particularly with natural rubber production leading to deforestation and synthetic rubber contributing to plastic pollution.

Innovation and Technological Advancements

Advances in polymer chemistry have led to the development of new rubber materials with enhanced properties like improved heat resistance, better wear and tear durability, and greater flexibility.

Regulatory and Safety Standards

Rubber products must comply with various regulatory and safety standards, depending on their application. For example, medical-grade rubber must meet stringent health regulations, while automotive rubber components must adhere to safety and performance standards.

Polymer Products

- Silicone Rubber Hardness 20 to 90° Shore A

- EPDM Rubber

- Nitrile Rubber

- Chloroprene Rubber

- Natural Rubber

- SBR

- FKM Rubber

- HNBR

Rubber Products

- Pure Rubber Diaphragms

- Rubber Grommets

- Rubber Bellows

- Rubber gaskets

- Rubber seals

- Rubber Foots

- Metal with Rubber Bonded Products

- Rubber with adhesive bonded products

- O Rings

Application

- Automotive Application

- Electronic Application

- Water Application

- Food application

- Oil and gas Application

SEALS WITH METAL TO RUBBER BONDED PRODUCTS

SILICONE PRODUCTS

RUBBER SHEET DIE CUTS

Join with us

Have questions or need assistance?