Precision and Accuracy

Die-cutting in polymer industries allows for high precision and accuracy in cutting complex shapes and patterns. This precision is critical for ensuring that parts meet exact specifications, especially in industries like automotive, electronics, and medical devices.

Material Versatility

Die-cutting can be used on a wide range of polymer materials, including but not limited to plastics, rubber, foam, and films. This versatility allows manufacturers to create custom components for various applications, from gaskets and seals to decorative elements.

Cost-Effectiveness

The initial setup cost of creating the die is offset by the ability to produce large quantities of uniform parts quickly and efficiently, reducing material waste and labor costs.

Speed and Efficiency

The die-cutting process is highly efficient, enabling rapid production of parts. Once the die is created, the process can run continuously, producing hundreds or even thousands of parts in a short time, making it ideal for high-volume production.

Customization and Flexibility

Die-cutting offers significant flexibility in terms of design and customization. Manufacturers can create dies that produce parts with intricate designs, multiple layers, or special features such as adhesive backing or perforations, tailored to the specific needs of the application.

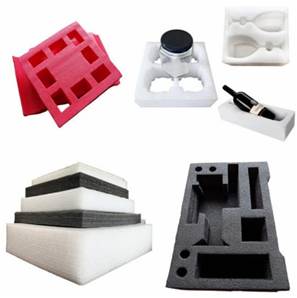

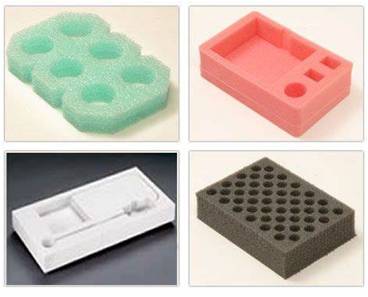

Foam Die-Cut Products

- Custom die-cut foam inserts

- Foam packaging materials

- Foam shipping containers

- Foam gaskets

- Foam seals

- Foam filters

- Foam soundproofing materials

- Foam vibration damping materials

- Foam thermal insulation materials

Die Cuts

- Foam Die cuts

- Adhesive Tape Die cuts

- Solid Rubber Die cuts

DIE CUTS

DIE CUTS WITH BONDING